Spring 2023

Peristaltic Pump

The task:

Advanced Arduino Project

As I’ve progressed my education as a technician at Dawson College, I’ve become more fascinated by the application of engineering in different fields. In the medical field, precise and reliable machines are necessary to perform advanced surgeries. For example, when a patient needs their lungs or heart to be operated on, surgeons need to reroute their circulatory system to an external pump. This is called a Cardiopulmonary Bypass and it’s what I elected to build for my project.

Project Elements

Medical Research

Coding and Wiring

For this project I wanted to get as close as possible to the requirements the human needs during a cardiopulmonary bypass. For example, I wanted to be able to produce the same flow

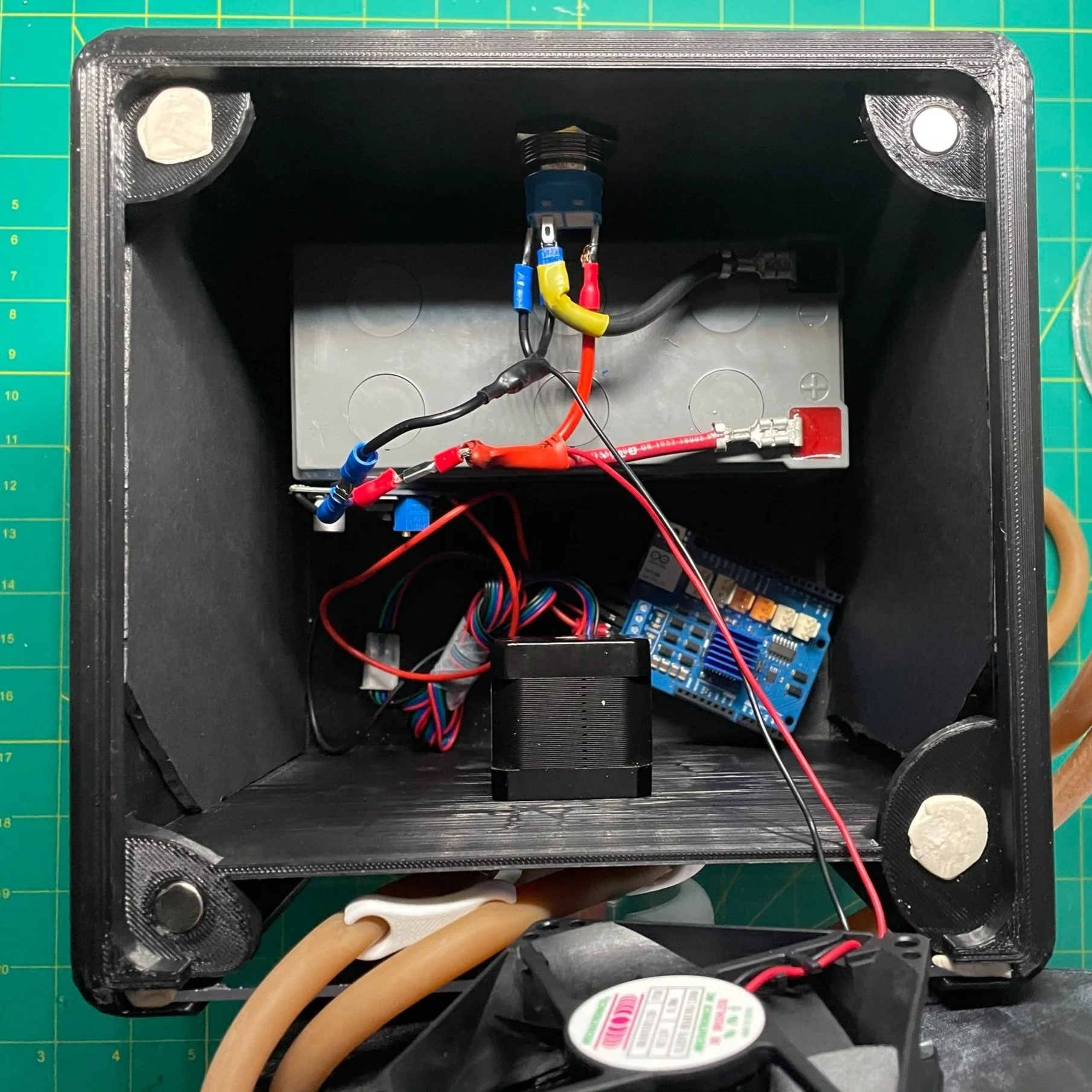

I not only wanted to make a functional prototype, but I also wanted to make something that was visually clean and easy to use. For this, I added a cooling fan and vents to allow the Arduino board and stepper motor to be enclosed and work at a normal temperature. I used a battery to allow the pump to function independently from a computer or wall outlet. This proved especially useful in demos and presentations. I also wrote the code so that I could adjust the flow of fluids using a unit in millilitres per second, which makes it possible to easily simulate different blood flows.

Pump and Housing Design

The main goal for the housing was to create an easy prototype platform on which I can easily add, replace, or modify different components as the project advanced, therefore it’s pretty simple. The lid magnetically fits to the top of the housing, making it easy to access the internal components. The peristaltic pump itself it is secured by 4 easy to access screws, allowing me to replace it frequently to test different pump cases and rotors.

Calibration and Testing

To ensure that my design was sound and that this machine could run for long periods of time, similar to that of cardiopulmonary bypass,

Learnings

For every new project I do, I try to strive ever closer to a clean and finished project. For this project, I put a significant emphasis on cooling and cleanliness. No parts overheated, the assembly is rugged and can withstand transportation, and the machine can be started without opening the housing. Were I to continue this project, I would redesign the rotor case and try different surfaces for the tubing to compress against to increase flow. Using a 3 arm rotor would increase resistance, but could help stabilize the pulses in fluid pressure.

Teammates

-

For this project I decided to try working alone. It’s something I enjoyed because I’ve dreamt of doing this project for a while, meaning it turned out exactly as I imagined.