Machining Exercises

Throughout my education, I’ve worked on many small projects teaching me different manufacturing processes used in the metal-working industry. Each project increased in complexity to give us the skills to be able to manufacture any parts for our own projects

Inter-fitting Parts

To learn the basics of machining, we were required to make a set of inter-fitting parts. I performed basic facing and turning as well as milling and knurling

C-Clamp

The biggest skill learned for this project was everything threads. I learned about the tolerances of threads, we machined the threaded rod, we tapped the milled block.

In this C-clamp project we also worked with brass and learned how to make contour passes on the mill.

After the course, I amateurly gave the body a cheap coat of paint to stop it rusting

Mallet

The mallet project thought us to calculate certain aspects of a part to obtain a certain dimension. For example, the handle tapers down to 3/4 of the shaft’s diameter over a set distance. We also learned to use different tooling.

Gears

The gears were taught us how to approach mutliple procedures on a single part. We learned about the geometry of gears and how to machine them to spec.

Spring Center

The spring center project was the first tool we would make that we would go on to use extensively. The outer diameters of the shaft were turned precisely to prevent any play in its travel, which would render it useless in real application.

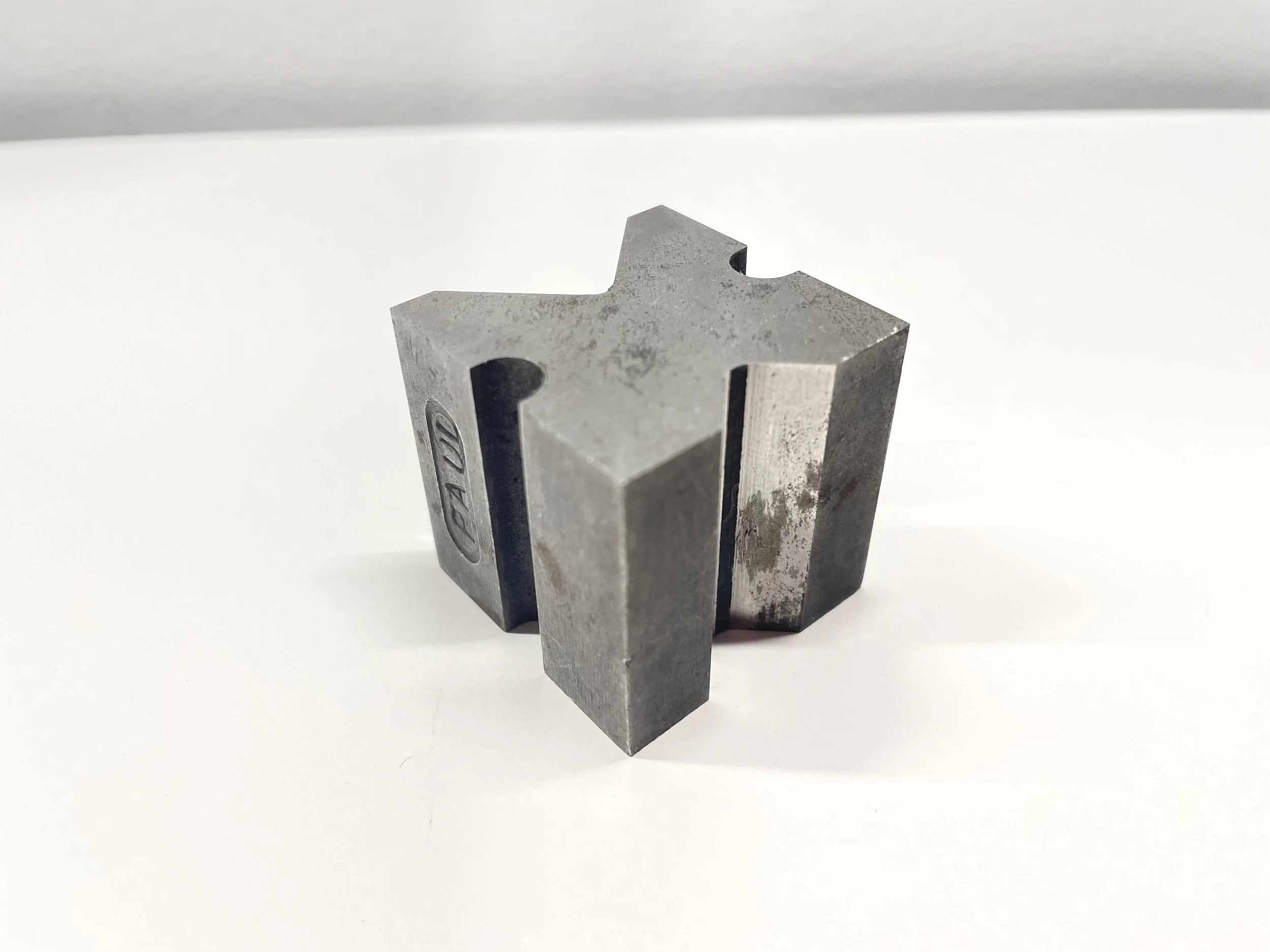

V-Block

The V block was the most complex single part to manufacture due to the precision requirements. Milling operations were done tediously to meet position tolerances. After being hardened in the furnace, the extreme faces were ground to a distance of withing half a thou.